Why We Use Hermann Oak Leather

on 27th May 2020

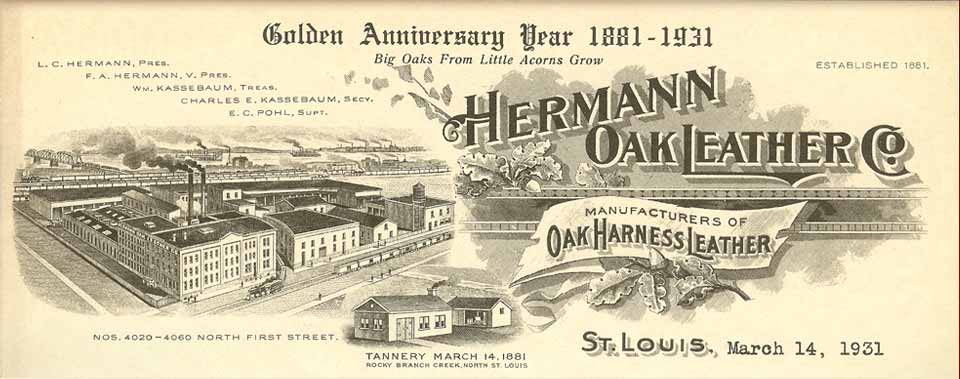

Hermann Oak is one of the last tanners of vegetable-tanned leather in the world still using the traditional system of a “pressed yard.” Most others have switched to newer systems, either Liritan or drum-tanned; these are quicker (for higher turnover and lower cost), whiter in color, and easier to control, yet they all contain various kinds of salts which Hermann Oak leathers do not.

Hermann Oak has tested these new tannages, and has elected to stay with their traditional tannage used since 1881 by four generations of tanners. They feel the resulting leather has distinct advantages to the end-user in the industries that they serve.

The advantages to this traditional “pressed yard” tannage of leather at Hermann Oak that they observe, and that they hear from customers, are:

Temper and “Hand.” Their leather starts out a little firmer than others, which many people refer to as “body.” Most importantly, it maintains its temper throughout its life. (Their leather has no salt residues because they do not use salt in their tanning process; salt will draw in moisture, which softens leather over time.)

- Shape. Their leather maintains its shape throughout its life. Holsters hold their shape.

- Color. Their leather maintains a rich mahogany color over the years. Other leathers turn a dull brown. The “enamel” on their grain (the very thin film of fingernail-like substance that gives skin and full-grain leather its shine) is thick, strong and naturally tanned, which repels dust and dirt.

- Oiling. Their leather oils up evenly and richly, bringing out the natural colors of the underlying bark.

- Oil Uptake / Weight. The density of their leather keeps it from taking on too much oil during cleaning. Saddles made with their leather do not gain nearly as much weight over time as do saddles made with other leathers.

- Stretch. Their firmer tannage means less stretch in the leather.

- Piping. There is less piping in their leather. (Piping are the waves that form when leather is bent grain-in.) Their grain is more firmly attached to the corium.

- Carving, Stamping, and Tooling. Customers tell them how well the leather does all these.

- Molding and Shaping. Customers tell them how soft the leather becomes when wet, yet how well it returns to its firm base when dried. This is critical whether forming holsters.

Hermann Oak performs other processes that are critical to tanning a completely naked, full-grain leather. These processes add cost, mostly in additional machinery, building space, and capital tied up in more work-in-process than other tanneries. They have found these practices to be a key component to their quality, and worth every penny of the additional cost.

Two-day Liming. Most other tanners take only one day. Their two-day process is less astringent and more gentle to both fibers and enamel. The liming is meant to swell the fibers, remove the hair, and remove the epidermis (a thin 1/10 oz membrane on the top of the hide) while preserving the enamel (another thin, 1/10 oz membrane between the epidermis and the grain, similar to a fingernail, which gives skin and leather its shine).

- High-float Liming. Most chrome tanners heavily load their unhairing drums, often loading above the gudgeon, using less than 100% water (the “float”). They unhair in paddles using a 300% float. This is less abrasive to the enamel, and allows time for the wrinkles and draw to better “let out.” However, it requires more water and chemicals, all of which must be treated in their wastewater plant at substantial expense.

- Scudding. We put the leather through an additional custom-designed machine to remove the scud, or hair root. Few other tanners have this step.

- Close fleshing. They clean up the backside as best as possible.

- Lime splitting. Their Strap-Tooling-Holster-Latigo lines are lime split to relax the fibers at an early stage, a difficult mechanical step in the limed state that most tanners have abandoned.

- No “pickling.” They add neither salt nor acid before tanning.

- Long tanyard. Their tanning system takes up to five weeks for the thickest leather. Systems like Liritan take two weeks or less. Vegetable tannages in a drum take as little as two days. Chrome tanning takes less than a day.

- Expensive acids. They use mainly organic acid to be compatible with their organic tannage, not the inorganic sulfuric acid used by most other tanners. This substantially lowers the chance of “acid rot” in their leather over long periods of time under humid conditions.

- Under-loaded bleach/fatliquor drums. They place fewer sides in each drum than other tanners, for higher quality.

- Controlled drying. They will take as long as three days to dry their thickest leather. This prevents over-drying which removes “bound” water, and which is irreversible.

- Trimming. They trim off what you can’t use.

- Hand-set Harness leather. Their Harness is so heavily stuffed with beef tallow that it will not go through our setting machines. It must be set with a small hand-operated setter and a slicking blade. It then takes a full week to dry, since it is as difficult for the water to escape as it is for water to reenter. They have found no other leather in the world that contains as much “stuffing” tallow as our Harness.

- Flesh. They finish the flesh on their “English” Bridle Leather (EBL) to a higher degree to lock down both fibers and color.

- Large inventory of tanned leather. They hold between $2 and $3 million of tanned yet unfinished leather to ensure consistent delivery of the type, grade, and thickness that we require.

- Customized finishing. Leather made to your specifications.

- Service with a smile.